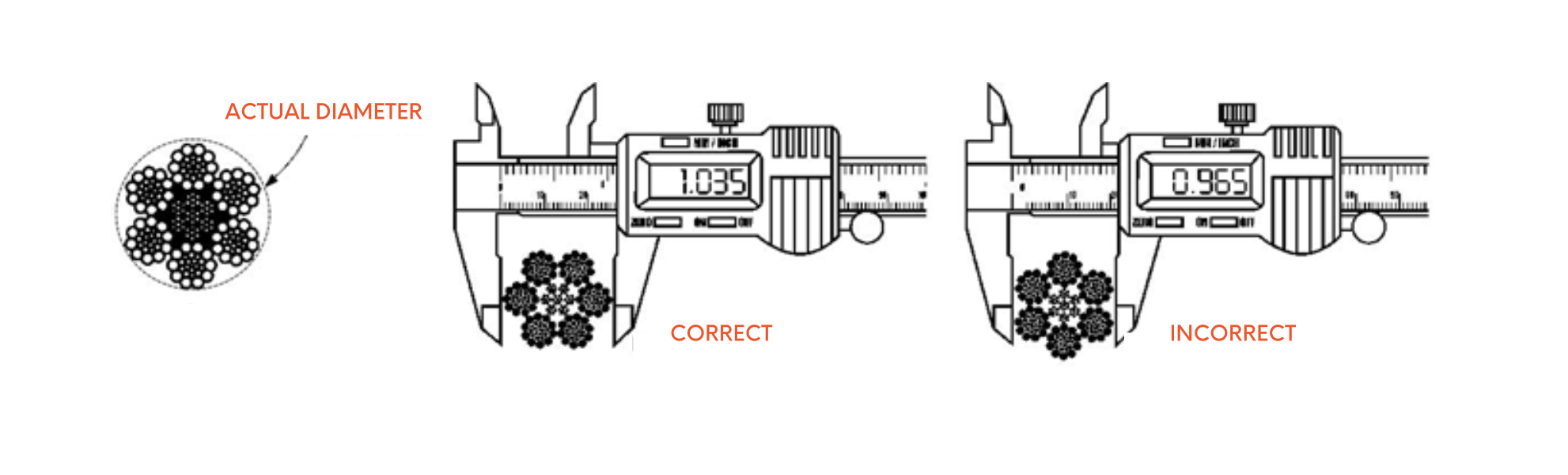

01. Wires that form the strand

02. Multi-wire strands laid helically around a core

03. The core

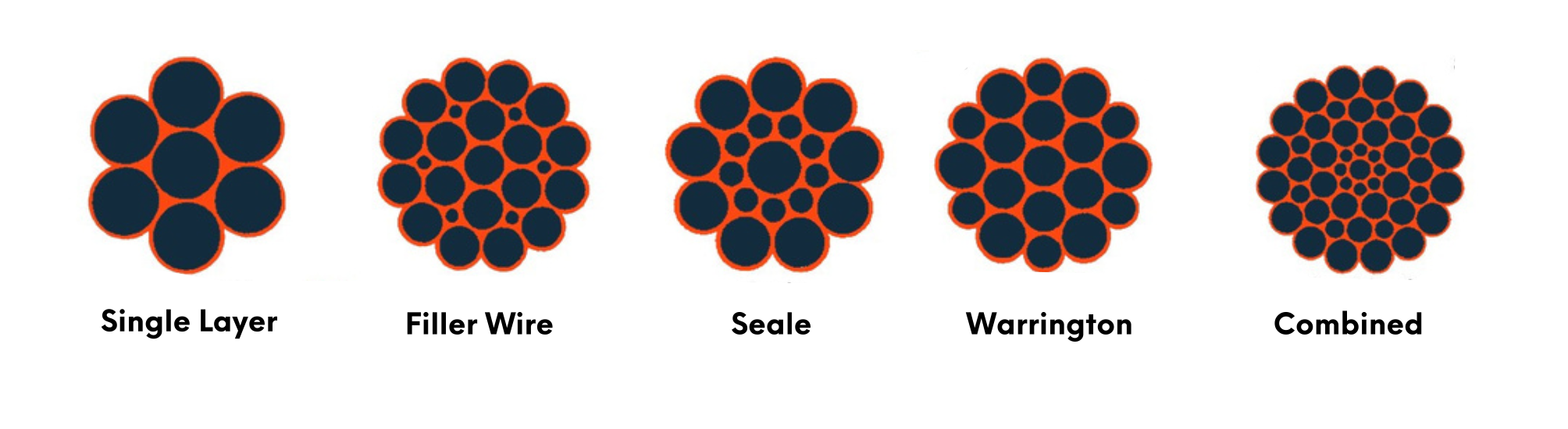

Wire for ropes are made in several materials and types. These may include steel, iron, stainless steel, and so on. By far, the most widely used material is high-carbon steel. This is available in a variety of grades, each of which has properties related to the basic curve for steel rope wire. Wire rope manufacturers select the wire type that is most appropriate for the requirements of the finished product. Strands are made up of three or more wires, laid in any one of many specific geometric arrangements, or in a combination of steel wires with some other materials such as natural or synthetic fibers. It is conceivable that a strand can be made up of any number of wires, or that a rope can have any number of strands. Right below, we provide you with a complete description of wire rope constructions. Wire rope identification is not only done by its component parts, but also by its construction, i.e., by the way, the wires have been laid to form strands, and by the way, the strands have been laid around the core.

The core is the foundation of a wire rope. If the core (IWRC) cannot support the compressive load imposed, the rope will lose its clearance between strands and its service life would be shortened.

Steel cores (WSC or IWRC) should be used when there is any evidence that a Fiber core will not provide adequate support. Also, if the temperature of the environment may be expected to exceed 180° (82°C) steel cores must be used.

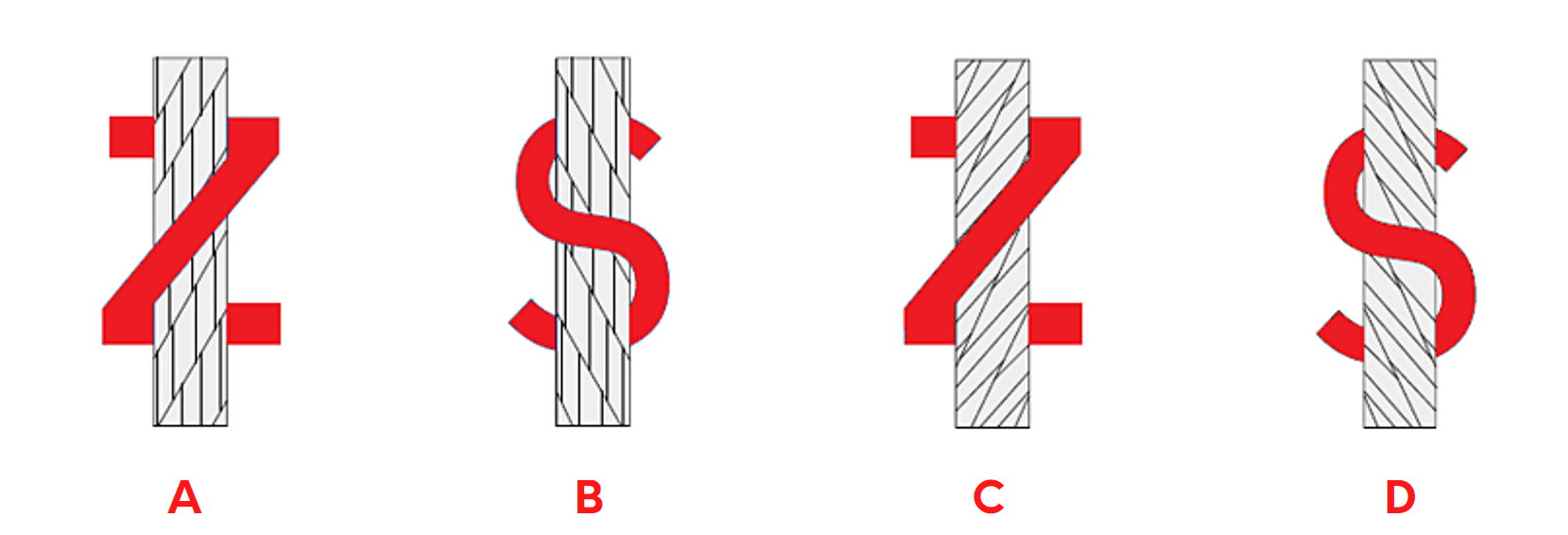

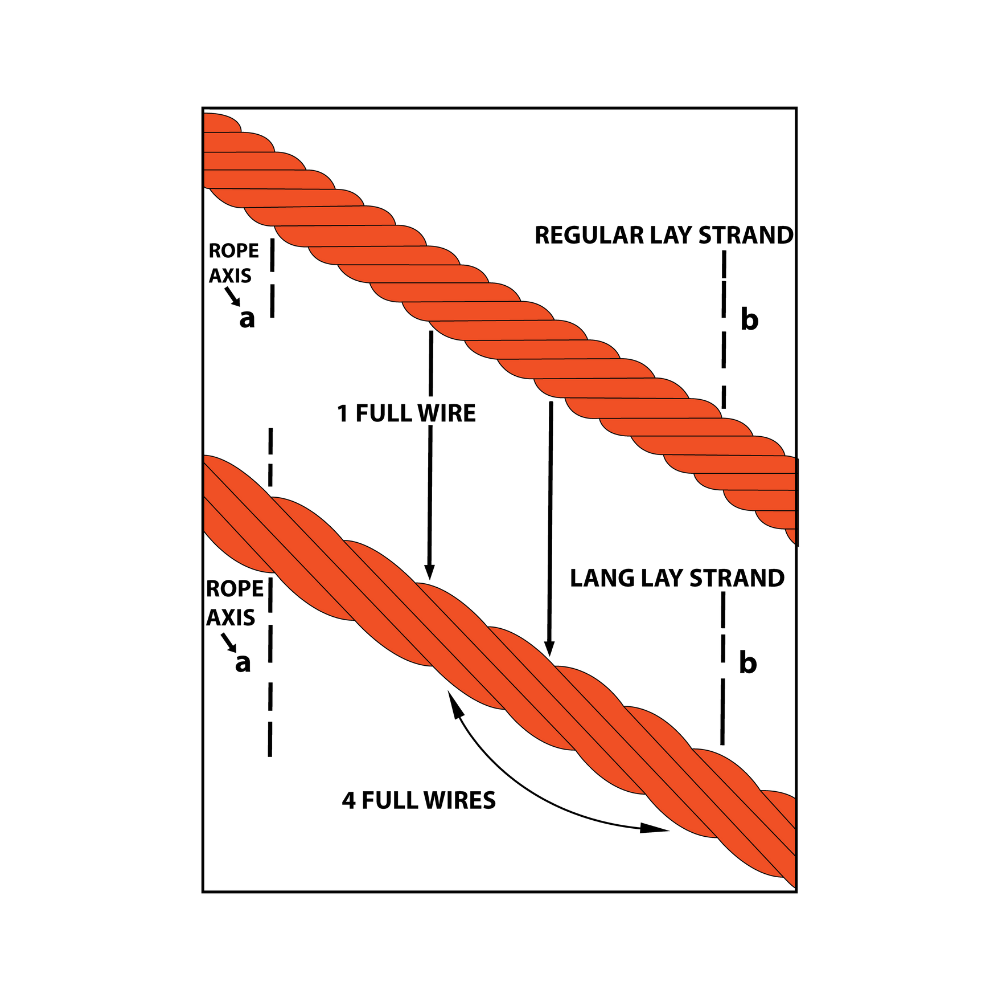

The first two (“A” and “B”) show Regular Lay Ropes. The “C”& “D” are the types known as Lang’s Lay Ropes. Note that the Wires in Regular Lay Ropes appear to line up with the axis of the Rope whereas in Lang’s Lay Ropes, the Wires form an angle with the axis of the Rope.

This difference in appearance is a result of variations in manufacturing techniques. Regular Lay Ropes are made so that the direction of the Wire Lay in the Strand is opposite to the direction of the Strand Lay in the Rope, whereas the Lang’s Lay Ropes are made with both Strand Lay and Rope Lay in the same direction. The “E” called alternate Lay consists of alternating Regular and Lang’s Lay Strands.

To summarize, a Wire Rope consists, in most cases, of three components: wires, strands, and a core. To these may be added what can be considered a fourth component: The Wire Rope’s Lubricant – a factor that’s extremely vital to the satisfactory performance & life of most operating ropes.

It is important to understand the reasons for the advantages of Lang Lay Ropes. Let’s consider their fatigue and bending properties. The figure shows, in part, how the Lang’s Lay construction characteristics result in greater fatigue resistance than is found in Regular Lay Ropes. Note how the axis of the Wire relates to the axis of the Rope in both cases.

When the regular Lay Rope is bent, the same degree of bend is imparted to the crowns of the outer wires. Superior fatique life in Lang’s Lay Ropes is also attributable to the longer exposed length of its outer wires. In the upper depiction of a Regular Lay Rope, the valley-to-valley length of individual wires is about 7/8″, the length of the Lang’s Lay Wires in the lower photograph is about 1- 1/8″ or say, 30% longer. Bending the Lang’s Lay Ropes results in less axial bending of the outer wires and greater torsional flexure. These combined stresses notwithstanding, the Lang’s Lay Ropes display 15 to 20% superiority over Regular Lay Ropes when bending is the principal factor affecting the service life.

Finally, the worn crown of the Regular Lay Wire combined with its shorter exposed length permits the wire to spring away from the rope axis. Subsequent passage on and off a sheave or drum results in fatigue breakage. However, Lang’s Lay Ropes have two important limitations. First, if either end is not fixed, it will rotate severely when under load, and secondly, it is less able to withstand crushing action on a drum or sheave, than is Regular Lay Rope. Hence, Lang’s Lay Ropes should not be operated without being secured against rotation at both the ends and nor should they be operated over minimum-sized sheaves or drums under extreme loads. Additionally, poor drum winding conditions are not well tolerated by Lang’s Lay Ropes.

Pre-forming is a process in Wire Rope manufacturing wherein the strands and their wires are formed-during fabrication to the helical shape that they will ultimately assume in the finished rope or strand. Another equally significant process in the manufacturing of Wire Ropes is Post-Forming. As the name suggests, this process comes “after” the strands have taken formation. Strands once formed, are made to pass through a high-pressure zig-zag-like formation controlled by Rollers made of special steel. This process is aimed at releasing any process-stresses that may have been left in strands at the formation stage and once a strand has passed through this process, all stress has been drained out of it and it’s ready to take shape of a rope it will eventually be closed into.

Hence, a manufacturer receiving an order for a 6 x 19 Rope may assume this to be a class reference and could possibly furnish any construction within this category. But, should the job require the special characteristics of a 6 × 25 Filler Wire, and a 6 x 19 Seale is supplied in its stead, the shorter service life may be the result. To avoid such misunderstandings, the safest procedure is to order a specific construction. In an event where the specific construction is not known or is under doubt, the Rope should be ordered by class along with a description of its end-use. Identification of Wire Rope in class groups facilitates selection on the basis of strength and weight since it is a customary domestic industry practice that all ropes (from a given manufacturer) within a class have the same nominal strength and weight. As for other-functional characteristics, these can be obtained by referencing the specific construction within the class.

Only three wire ropes under the 6x 19 classification actually have 19 wires, 6x 19 (Two-Operation) 6 x 19 Seale (S), and 6 x 19 Warrington (W). All the rest have different wire counts. In the 6x 37 class there is a greater variety of wire constructions. The commonly available constructions in the 6x 37 class include: 6 × 31 Warrington Seale (WS), 6 x 36 WS, 6 x 41 Seale Filler Wire (SFW), 6 x 41 WS, etc. – none of which contain exactly 37 wires.